Business Plan for Sheet Metal Fabrication Business

Dunrite Metal Fabricators, Inc. "Next 5 Years"

Executive Summary

- Business Name: Dunrite Metal Fabricators, Inc.

- EIN: 59-2932106

- Location: Clearwater, FL

- Business Description: Dunrite Metal Fabricators, Inc. is a premier provider of custom sheet metal fabrication services with a proven track record spanning over 30 years. We specialize in high-quality, innovative solutions tailored for diverse industries including construction, automotive, industrial, and aerospace.

- Mission Statement: To deliver superior sheet metal products through exceptional craftsmanship, innovative solutions, and excellent customer service, maintaining a focus on sustainability and community engagement.

- Vision Statement: To be the most trusted metal fabrication partner in the United States by continuously improving our processes, expanding our product offerings, and exceeding customer expectations.

Business Objectives

- Achieve Sustainable Growth: Target an annual revenue growth of 15%, aiming to reach $5 million in profits by the end of Year 5.

- Quality Leadership: Maintain a customer satisfaction rating of at least 95% through rigorous training and continuous improvement programs.

- Innovative Product Development: Launch 2-3 new product lines annually, adapting to market demand.

- Expand Client Base: Increase the number of active clients by 20% each year through enhanced marketing outreach and networking.

Market Analysis

- Target Market:

- Construction: Local contractors requiring custom metal frameworks and fittings.

- Automotive: Partnerships with automotive manufacturers and repair shops for aftermarket components.

- Industrial: Supplying metal products and components for various industrial applications, including machinery frameworks, custom parts, and assembly components.

- Aerospace: Collaborating with aerospace manufacturers on high-precision parts.

- Market Trends:

- Growing demand for sustainable manufacturing practices and environmentally friendly products.

- Increasing automation and integration of smart technologies in fabrication processes.

- The rise in prefabricated steel structures as a cost-effective and eco-friendly construction solution.

- Competition Analysis:

- Analysis of local and national sheet metal fabrication competitors, identifying key players, market share data, and differentiation strategies.

- Dunrite's competitive advantage lies in its established reputation for quality, a skilled workforce, and strong customer relationships.

Marketing Strategy

- Brand Positioning: Establish Dunrite as a premium provider known for reliability, quality, and exceptional customer service, leveraging a strong online presence and trusted referrals.

- Sales Channels:

- Direct Outreach: Focused engagement with local contractors and business clients through dedicated sales personnel.

- Digital Marketing: Implement comprehensive SEO strategies, PPC advertising, and content marketing (blogging, case studies) to enhance online visibility and lead generation.

- Promotional Strategies:

- Community Engagement: Sponsor local events and participate in trade shows to promote brand visibility while emphasizing Dunrite's commitment to community support.

- Customer Testimonials: Actively seek feedback from satisfied customers to create compelling testimonials and case studies showcasing successful projects.

Operations Plan

- Facility Requirements:

- Modern manufacturing facility in Largo, FL with a minimum of 20,000 square feet to accommodate advanced machinery, inventory storage, assembly, and R&D.

- Equipment Needed:

- Investment in CNC machines, laser cutters, plasma cutters, automated welding systems, and bending machines to improve production efficiency and quality.

- Production Processes:

- Implement lean manufacturing techniques to minimize waste and optimize workflow.

- Continuous employee training programs to maintain the highest quality standards and exposure to new technologies.

- Sustainability Initiatives:

- Develop a recycling program for scrap metal and explore the use of renewable energy sources such as solar panels to reduce the carbon footprint. This commitment to sustainability can attract environmentally conscious clients.

Key Employees

- Operations Manager:

- Responsibilities: Oversee daily operations, manage staff schedules, and ensure production efficiency. Needs experience in lean manufacturing and operational excellence.

- Qualifications: Minimum 7 years in manufacturing operations management.

- Design Engineer:

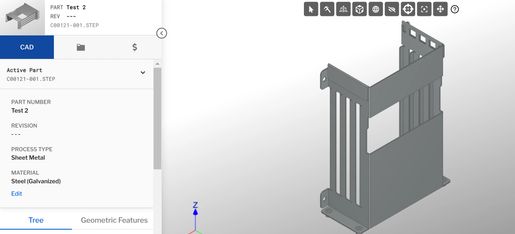

- Responsibilities: Create and optimize designs using CAD software, tailoring products to customer needs. Must collaborate with production staff to ensure feasibility.

- Qualifications: Bachelor’s degree in Mechanical Engineering with 5+ years of experience.

- Fabrication Technicians:

- Responsibilities: Operate cutting, welding, and finishing equipment while adhering to safety and quality standards.

- Qualifications: Technical training in welding or metal fabrication, experience is a plus.

- Quality Control Inspector:

- Responsibilities: Implement quality assurance programs to monitor product quality throughout the production process and ensure compliance with industry standards.

- Qualifications: Experience in quality control within manufacturing, knowledge of ISO standards preferred.

- Sales and Marketing Manager:

- Responsibilities: Develop and execute marketing strategies to attract new clients and maintain relationships with existing customers. Responsible for market research and identifying growth opportunities.

- Qualifications: 5+ years of experience in B2B sales or marketing, preferably in the manufacturing industry.

- Administrative Support Staff:

- Responsibilities: Manage logistics, office administration, accounting functions, and customer service inquiries to ensure smooth operational workflow.

- Qualifications: Proficient in office software and experienced in administrative roles within manufacturing environments.

- R&D Specialist:

- Responsibilities: Lead research initiatives for new materials and innovative fabrication techniques; develop prototypes and assess their viability for production.

- Qualifications: Bachelor’s or Master’s degree in Materials Science or Engineering with a focus on research.

Financial Plan

Startup Costs:

- Estimated Equipment Investment: $500,000 for advanced manufacturing machinery including CNC machines, laser and plasma cutters, and welding equipment.

- Facility Improvements: $200,000 for renovations to ensure compliance with modern manufacturing standards (including safety and energy efficiency).

- Initial Working Capital: $100,000 to cover operational expenses for the first few months (utilities, payroll, and inventory).

- Marketing Strategies: Allocate $50,000 for initial marketing campaigns and digital marketing efforts to build brand visibility.

Revenue Projections:

- Year 1: Establish foundational contracts projecting $1 million in revenue, targeting completion of baseline projects and securing repeat clients.

- Year 2: Expand to $2 million by increasing the customer base and launching new product lines, leveraging established relationships and marketing efforts.

- Year 3: Reach $3.5 million through enhanced marketing in new segments and diversifying client industries.

- Year 4: Achieve $4.5 million through operational efficiencies, improved production processes, and expanded service offerings.

- Year 5: Target consistent profits of $5 million by entering federal and larger commercial contracts, investing in technology upgrades, and shifting towards high-margin products.

Funding Requirements:

- External Funding Needs: Total funding requirement of roughly $400,000 sourced from various avenues such as bank loans, venture capital, and possible grants that support manufacturing and technology investments.

- Investor Goals: Identify returns within two years by demonstrating growth through scalable operations and new market penetration.

Cost Management Strategy:

- Implement stringent cost control measures to monitor expenses and identify areas for efficiency improvements, reducing overhead and minimizing waste through lean manufacturing principles.

- Scheduled financial reviews to assess performance against projections, ensuring quick pivots in strategy or operations as necessary.

Break-even Analysis:

- Expected break-even point of around 18-24 months , considering initial investment and projected operational costs. Use this analysis to inform pricing strategies and needed sales volumes to meet profitability objectives.

Conclusion

This comprehensive business plan positions Dunrite Metal Fabricators, Inc. as a robust player in the sheet metal fabrication industry, with a clear pathway to achieving $5 million in profits consistently. By focusing on quality, operational efficiency, innovative product development, and strong community engagement, Dunrite can sustain its legacy of excellence while addressing the needs of a diverse clientele. The company will continue to adapt to market changes, invest in its workforce, and utilize state-of-the-art technologies to secure an advantageous position in the competitive landscape of metal fabrication.

Going Forward...

Mission:

"At Dunrite Metal Fabricators, Inc., our mission is to deliver superior custom metal fabrication solutions that blend exceptional craftsmanship with innovative technology, all while fostering lasting relationships with our clients and committing to sustainable practices."

Company Motto:

"Fabricating Excellence, Building Trust, Innovating for Tomorrow."

DunriteMetal.com

12099 44th Street North, Clearwater, FL 33762, US

Office (727) 299-9242 Cell (727) 251-9348

Need a price now?

Hit the button below.